|

Ningbo Xingde Magnet Co., Ltd.

|

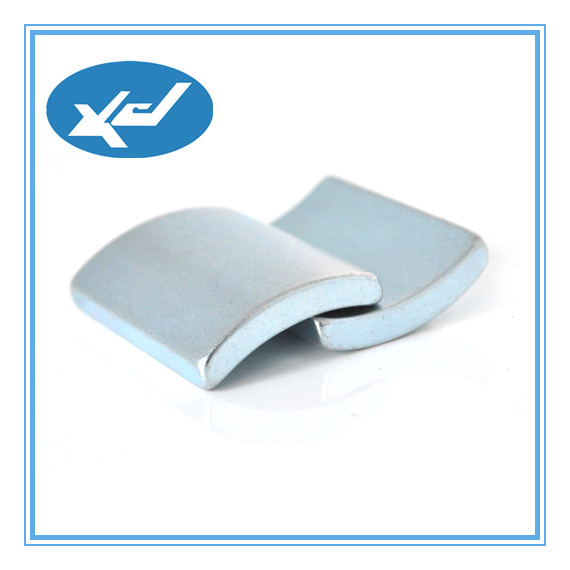

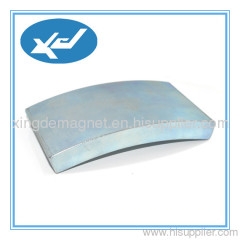

40H Permanent NdFeB magnet segment shape

| Price: | 0.1 USD |

| Payment Terms: | T/T,L/C;PAYPAL |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Machining &Tolerance of 40H Permanent NdFeB magnet Arc

Generally, NdFeB magnets must be machined using diamond-grinding techniques. Sometimes, mac

The north pole of a magnet is the pole that, when the magnet is freely suspended, points towards the Earth's North Magnetic Pole which is located in northern Canada. Since opposite poles (north and south) attract, the Earth's "North Magnetic Pole" is thus actually the south pole of the Earth's magnetic field.

As a practical matter, in order to tell which pole of a magnet is north and which is south, it is not necessary to use the Earth's magnetic field at all. For example, one method would be to compare it to an electromagnet, whose poles can be identified by the right-hand rule. The magnetic field lines of a magnet are considered by convention to emerge from the magnet's north pole and reenter at the south pole.

Material Code | Br | Hcj | BH(max) | Max Working temperature | ||||

KGs | T | Koe | KA/m | MGOe | KJ/m3 | (Tw) | ||

N52 | 1430-1480 | 14.3-14.8 | >=11 | >=876 | 50-53 | 398-422 | 80℃ | |

N50 | 1400-1450 | 14.0-14.5 | >=11 | >=876 | 48-51 | 398-423 | 80℃ | |

N48 | 1380-1420 | 13.8-14.2 | >=12 | >=955 | 46-49 | 366-390 | 80℃ | |

N45 | 1320-1380 | 13.2-13.8 | >=12 | >=955 | 43-46 | 342-366 | 80℃ | |

N42 | 1280-1320 | 12.8-13.2 | >=12 | >=955 | 40-43 | 318-342 | 80℃ | |

N40 | 1250-1280 | 12.5-12.8 | >=12 | >=955 | 38-41 | 302-326 | 80℃ | |

N38 | 1220-1250 | 12.2-12.5 | >=12 | >=955 | 36-39 | 287-310 | 80℃ | |

N35 | 1170-1220 | 11.7-12.2 | >=12 | >=955 | 33-36 | 263-287 | 80℃ | |

50M | 1400-1450 | 14.0-14.5 | >=14 | >=1114 | 48-51 | 382-406 | 100℃ | |

48M | 1360-1430 | 13.6-14.3 | >=14 | >=1114 | 46-49 | 366-390 | 100℃ | |

45M | 1320-1380 | 13.2-13.8 | >=14 | >=1114 | 43-46 | 342-366 | 100℃ | |

42M | 1280-1320 | 12.8-13.2 | >=14 | >=1114 | 40-43 | 318-342 | 100℃ | |

40M | 1250-1280 | 12.5-12.8 | >=14 | >=1114 | 38-41 | 302-326 | 100℃ | |

38M | 1220-1250 | 12.2-12.5 | >=14 | >=1114 | 36-39 | 287-310 | 100℃ | |

35M | 1170-1220 | 11.7-12.2 | >=14 | >=1114 | 33-36 | 263-287 | 100℃ | |

33M | 1130-1170 | 11.3-11.7 | >=14 | >=1114 | 31-33 | 247-263 | 100℃ | |

30M | 1080-1130 | 10.8-11.3 | >=14 | >=1114 | 28-31 | 223-247 | 100℃ | |

48H | 1370-1430 | 13.7-14.3 | >=17 | >=1353 | 46-49 | 366-390 | 120℃ | |

45H | 1320-1380 | 13.2-13.8 | >=17 | >=1353 | 43-46 | 342-366 | 120℃ | |

42H | 1280-1320 | 12.8-13.2 | >=17 | >=1353 | 40-43 | 318-342 | 120℃ | |

40H | 1250-1280 | 12.5-12.8 | >=17 | >=1353 | 38-41 | 302-326 | 120℃ | |

38H | 1220-1250 | 12.2-12.5 | >=17 | >=1353 | 36-39 | 287-310 | 120℃ | |

35H | 1170-1220 | 11.7-12.2 | >=17 | >=1353 | 33-36 | 263-287 | 120℃ | |

33H | 1130-1170 | 11.3-11.7 | >=17 | >=1353 | 31-34 | 247-271 | 120℃ | |

30H | 1080-1130 | 10.8-11.3 | >=17 | >=1353 | 28-31 | 223-247 | 120℃ | |

45SH | 1320-1380 | 13.2-13.8 | >=20 | >=1592 | 43-46 | 342-366 | 150℃ | |

42SH | 1280-1320 | 12.8-13.2 | >=20 | >=1592 | 40-43 | 318-342 | 150℃ | |

40SH | 1240-1280 | 12.5-12.8 | >=20 | >=1592 | 38-41 | 302-326 | 150℃ | |

38SH | 1220-1250 | 12.2-12.5 | >=20 | >=1592 | 36-39 | 287-310 | 150℃ | |

35SH | 1170-1220 | 11.7-12.2 | >=20 | >=1592 | 33-36 | 263-287 | 150℃ | |

33SH | 1130-1170 | 11.3-11.7 | >=20 | >=1592 | 31-34 | 247-271 | 150℃ | |

30SH | 1080-1130 | 10.8-11.3 | >=20 | >=1592 | 28-31 | 223-247 | 150℃ | |

40UH | 1240-1280 | 12.5-12.8 | >=25 | >=1990 | 38-41 | 302-326 | 180℃ | |

38UH | 1220-1250 | 12.2-12.5 | >=25 | >=1990 | 36-39 | 287-310 | 180℃ | |

35UH | 1180-1220 | 11.8-12.2 | >=25 | >=1990 | 33-36 | 263-287 | 180℃ | |

33UH | 1130-1170 | 11.3-11.7 | >=25 | >=1990 | 31-34 | 247-271 | 180℃ | |

30UH | 1080-1130 | 10.8-11.3 | >=25 | >=1990 | 28-31 | 223-247 | 180℃ | |

28UH | 1020-1080 | 10.2-10.8 | >=25 | >=1990 | 26-29 | 207-231 | 180℃ | |

38EH | 1220-1250 | 12.2-12.5 | >=30 | >=2388 | 36-39 | 287-310 | 200℃ | |

35EH | 1170-1220 | 11.7-12.2 | >=30 | >=2388 | 33-36 | 263-287 | 200℃ | |

33EH | 1130-1170 | 11.3-11.7 | >=30 | >=2388 | 31-34 | 247-271 | 200℃ | |

30EH | 1080-1130 | 10.8-11.3 | >=30 | >=2388 | 28-31 | 223-247 | 200℃ | |

28EH | 1040-1090 | 10.4-10.9 | >=30 | >=2388 | 26-29 | 207-231 | 200℃ | |

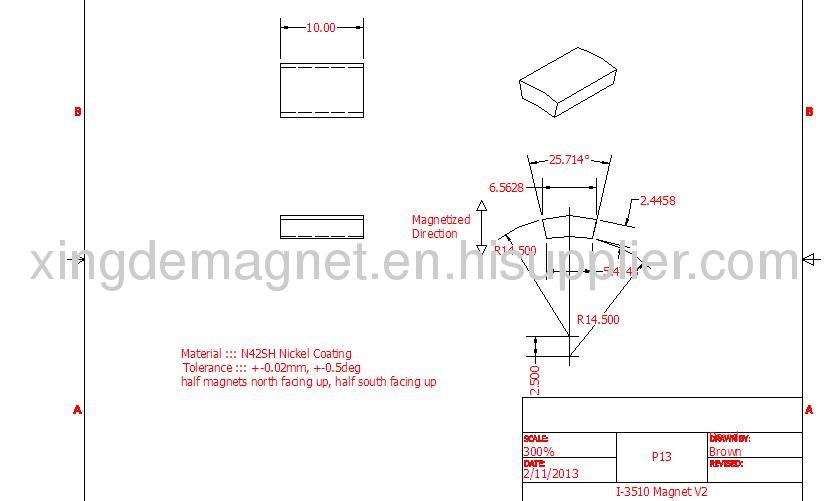

1, Michining &Tolerance of 40H sintered NdFeB magnet Arc shape

Generally, NdFeB magnets must be machined using diamond-grinding techniques. Sometimes, machining operations may be performed on NdFeB materials using carbide tools, but surface finishes thus obtained may be less than optimal.

The Standard tolerances for NdFeB magnets are +/- 0.1mm for ground dimensions, but sticter tolerances are possible if specially required.

2, Drawing picture of 40H sintered NdFeB magnet Arc shape

3, Photo of 40H sintered NdFeB magnet Arc shape

About Xingde,

Ningbo Xingde Magnet Co.,Ltd, located in southern surburb of Ningbo, who is specialized in production of up-to-date magnetic material- NdFeB, and technology development. Our company has advanced manufacturing process and test equipments, outstanding technologist of mangement and administration. Now with more than 3500 square meter workshop and nearly 200 staffs, we own the ability of annual production of over 1000 ton high performance sintered NdFeB magnets.

Our company was established in 1992, and the various products of NdFeB permanent magnets have characteristics of high-energy, high corrective force and high induction. The company passed ISO9001:2008 quality management system certification. "Conscientiousness and responsibility makes the customers satisfactory." is the management aim of our enterprise.

Ningbo Xingde Magnet Co.,Ltd would offer various NdFeB magnetic products with high quality and competitive price sincerely for each customer.