|

Ningbo Xingde Magnet Co., Ltd.

|

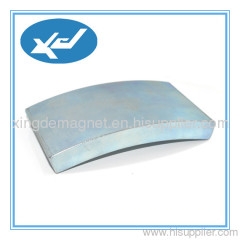

45SH Neodymium wind turbine Magnet Arc shape

| Price: | 0.1 USD |

| Payment Terms: | T/T,L/C,WU;PAYPAL |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Good quality sintered magnets.

Motor magnets with high working temperture such as 35SH, 38SH, 35 UH,35EH, use some small arc magnet

The performance of neodymium magnet

Unique dual-alloy process is developed and applied. The liquid phase of well-controlled auxiliary alloy composition can infiltratethe 2:14:1 phase grain sufficiently. Uniform rare-earth-rich phase is made around 2:14:1 grain by auxiliary alloy liquid phase, so as to increase value of Hcj. In the meantime, rare earth in auxiliary alloy liquid is stopped outside the principal phase by controlling sintering time and temperature, so that epitaxial layer of principal phase gets high anisotropy, and so to stop Js of principal phase to decrease. Magnet for Direct Drive Wind Generator has to be of very high comprehensive performance to stand harsh working environment and very long life time

Material Code | Br | Hcj | BH(max) | Max Working temperature | ||||

KGs | T | Koe | KA/m | MGOe | KJ/m3 | (Tw) | ||

N52 | 1430-1480 | 14.3-14.8 | >=11 | >=876 | 50-53 | 398-422 | 80℃ | |

N50 | 1400-1450 | 14.0-14.5 | >=11 | >=876 | 48-51 | 398-423 | 80℃ | |

N48 | 1380-1420 | 13.8-14.2 | >=12 | >=955 | 46-49 | 366-390 | 80℃ | |

N45 | 1320-1380 | 13.2-13.8 | >=12 | >=955 | 43-46 | 342-366 | 80℃ | |

N42 | 1280-1320 | 12.8-13.2 | >=12 | >=955 | 40-43 | 318-342 | 80℃ | |

N40 | 1250-1280 | 12.5-12.8 | >=12 | >=955 | 38-41 | 302-326 | 80℃ | |

N38 | 1220-1250 | 12.2-12.5 | >=12 | >=955 | 36-39 | 287-310 | 80℃ | |

N35 | 1170-1220 | 11.7-12.2 | >=12 | >=955 | 33-36 | 263-287 | 80℃ | |

50M | 1400-1450 | 14.0-14.5 | >=14 | >=1114 | 48-51 | 382-406 | 100℃ | |

48M | 1360-1430 | 13.6-14.3 | >=14 | >=1114 | 46-49 | 366-390 | 100℃ | |

45M | 1320-1380 | 13.2-13.8 | >=14 | >=1114 | 43-46 | 342-366 | 100℃ | |

42M | 1280-1320 | 12.8-13.2 | >=14 | >=1114 | 40-43 | 318-342 | 100℃ | |

40M | 1250-1280 | 12.5-12.8 | >=14 | >=1114 | 38-41 | 302-326 | 100℃ | |

38M | 1220-1250 | 12.2-12.5 | >=14 | >=1114 | 36-39 | 287-310 | 100℃ | |

35M | 1170-1220 | 11.7-12.2 | >=14 | >=1114 | 33-36 | 263-287 | 100℃ | |

33M | 1130-1170 | 11.3-11.7 | >=14 | >=1114 | 31-33 | 247-263 | 100℃ | |

30M | 1080-1130 | 10.8-11.3 | >=14 | >=1114 | 28-31 | 223-247 | 100℃ | |

48H | 1370-1430 | 13.7-14.3 | >=17 | >=1353 | 46-49 | 366-390 | 120℃ | |

45H | 1320-1380 | 13.2-13.8 | >=17 | >=1353 | 43-46 | 342-366 | 120℃ | |

42H | 1280-1320 | 12.8-13.2 | >=17 | >=1353 | 40-43 | 318-342 | 120℃ | |

40H | 1250-1280 | 12.5-12.8 | >=17 | >=1353 | 38-41 | 302-326 | 120℃ | |

38H | 1220-1250 | 12.2-12.5 | >=17 | >=1353 | 36-39 | 287-310 | 120℃ | |

35H | 1170-1220 | 11.7-12.2 | >=17 | >=1353 | 33-36 | 263-287 | 120℃ | |

33H | 1130-1170 | 11.3-11.7 | >=17 | >=1353 | 31-34 | 247-271 | 120℃ | |

30H | 1080-1130 | 10.8-11.3 | >=17 | >=1353 | 28-31 | 223-247 | 120℃ | |

45SH | 1320-1380 | 13.2-13.8 | >=20 | >=1592 | 43-46 | 342-366 | 150℃ | |

42SH | 1280-1320 | 12.8-13.2 | >=20 | >=1592 | 40-43 | 318-342 | 150℃ | |

40SH | 1240-1280 | 12.5-12.8 | >=20 | >=1592 | 38-41 | 302-326 | 150℃ | |

38SH | 1220-1250 | 12.2-12.5 | >=20 | >=1592 | 36-39 | 287-310 | 150℃ | |

35SH | 1170-1220 | 11.7-12.2 | >=20 | >=1592 | 33-36 | 263-287 | 150℃ | |

33SH | 1130-1170 | 11.3-11.7 | >=20 | >=1592 | 31-34 | 247-271 | 150℃ | |

30SH | 1080-1130 | 10.8-11.3 | >=20 | >=1592 | 28-31 | 223-247 | 150℃ | |

40UH | 1240-1280 | 12.5-12.8 | >=25 | >=1990 | 38-41 | 302-326 | 180℃ | |

38UH | 1220-1250 | 12.2-12.5 | >=25 | >=1990 | 36-39 | 287-310 | 180℃ | |

35UH | 1180-1220 | 11.8-12.2 | >=25 | >=1990 | 33-36 | 263-287 | 180℃ | |

33UH | 1130-1170 | 11.3-11.7 | >=25 | >=1990 | 31-34 | 247-271 | 180℃ | |

30UH | 1080-1130 | 10.8-11.3 | >=25 | >=1990 | 28-31 | 223-247 | 180℃ | |

28UH | 1020-1080 | 10.2-10.8 | >=25 | >=1990 | 26-29 | 207-231 | 180℃ | |

38EH | 1220-1250 | 12.2-12.5 | >=30 | >=2388 | 36-39 | 287-310 | 200℃ | |

35EH | 1170-1220 | 11.7-12.2 | >=30 | >=2388 | 33-36 | 263-287 | 200℃ | |

33EH | 1130-1170 | 11.3-11.7 | >=30 | >=2388 | 31-34 | 247-271 | 200℃ | |

30EH | 1080-1130 | 10.8-11.3 | >=30 | >=2388 | 28-31 | 223-247 | 200℃ | |

28EH | 1040-1090 | 10.4-10.9 | >=30 | >=2388 | 26-29 | 207-231 | 200℃ | |

1, Description for 45SH China Neodymium Stepping Motor Magnet Arc shape

Motor magnets with high working temperture such as 35SH, 38SH, 35 UH,35EH, use some small arc magnets to form a ring magnet, magnitizaion is through diameter, N-S and S-N.

2, Design for 45SH China Neodymium Stepping Motor Magnet Arc shape used in Stepping motor

3, Picture for 45SH China Neodymium Stepping Motor Magnet Arc shape

XINGDE magnet gets a more stable microstructure by adding microelement and using special ageing process for servo motor magnets. Through the technology, excellent magnetic properties are secured, to ensure XINGDE magnets are reliable and qualified to varius kinds of working environment