|

Ningbo Xingde Magnet Co., Ltd.

|

NdFeB magnets with strong force

| Price: | 0.1 USD |

| Payment Terms: | T/T,L/C;PAYPAL |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

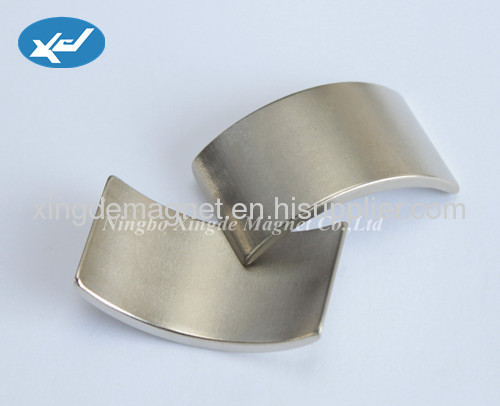

Strong force magnet

1. Grade: N35-N52, 30M-50M, 30H-48H, 30SH-45HS, 28UH-40UH, 28EH-35EH

2. Certificate: ISO9001:2008.

3. Usage: Industry, machines

Strong force NdFeB segment magnets details

1)Item: Rare earth permanent Magnet

2)Grade: N, M, H, SH, UH, EH

3)Coating: Znic,etc.

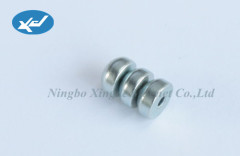

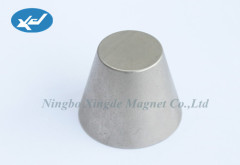

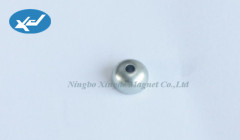

4)Size: Bespoke size

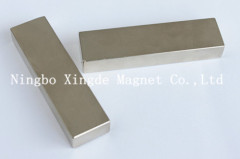

5)Shape: square

6)Usage: widely used in industry, electronics products, loudspeakers, motor, etc.

Performance of Strong force NdFeB segment magnets

Material Code | Br | Hcj | BH(max) | Max Working temperature | ||||

KGs | T | Koe | KA/m | MGOe | KJ/m3 | (Tw) | ||

N52 | 1430-1480 | 14.3-14.8 | >=11 | >=876 | 50-53 | 398-422 | 80℃ | |

N50 | 1400-1450 | 14.0-14.5 | >=11 | >=876 | 48-51 | 398-423 | 80℃ | |

N48 | 1380-1420 | 13.8-14.2 | >=12 | >=955 | 46-49 | 366-390 | 80℃ | |

N45 | 1320-1380 | 13.2-13.8 | >=12 | >=955 | 43-46 | 342-366 | 80℃ | |

N42 | 1280-1320 | 12.8-13.2 | >=12 | >=955 | 40-43 | 318-342 | 80℃ | |

N40 | 1250-1280 | 12.5-12.8 | >=12 | >=955 | 38-41 | 302-326 | 80℃ | |

N38 | 1220-1250 | 12.2-12.5 | >=12 | >=955 | 36-39 | 287-310 | 80℃ | |

N35 | 1170-1220 | 11.7-12.2 | >=12 | >=955 | 33-36 | 263-287 | 80℃ | |

50M | 1400-1450 | 14.0-14.5 | >=14 | >=1114 | 48-51 | 382-406 | 100℃ | |

48M | 1360-1430 | 13.6-14.3 | >=14 | >=1114 | 46-49 | 366-390 | 100℃ | |

45M | 1320-1380 | 13.2-13.8 | >=14 | >=1114 | 43-46 | 342-366 | 100℃ | |

42M | 1280-1320 | 12.8-13.2 | >=14 | >=1114 | 40-43 | 318-342 | 100℃ | |

40M | 1250-1280 | 12.5-12.8 | >=14 | >=1114 | 38-41 | 302-326 | 100℃ | |

38M | 1220-1250 | 12.2-12.5 | >=14 | >=1114 | 36-39 | 287-310 | 100℃ | |

35M | 1170-1220 | 11.7-12.2 | >=14 | >=1114 | 33-36 | 263-287 | 100℃ | |

33M | 1130-1170 | 11.3-11.7 | >=14 | >=1114 | 31-33 | 247-263 | 100℃ | |

30M | 1080-1130 | 10.8-11.3 | >=14 | >=1114 | 28-31 | 223-247 | 100℃ | |

48H | 1370-1430 | 13.7-14.3 | >=17 | >=1353 | 46-49 | 366-390 | 120℃ | |

45H | 1320-1380 | 13.2-13.8 | >=17 | >=1353 | 43-46 | 342-366 | 120℃ | |

42H | 1280-1320 | 12.8-13.2 | >=17 | >=1353 | 40-43 | 318-342 | 120℃ | |

40H | 1250-1280 | 12.5-12.8 | >=17 | >=1353 | 38-41 | 302-326 | 120℃ | |

38H | 1220-1250 | 12.2-12.5 | >=17 | >=1353 | 36-39 | 287-310 | 120℃ | |

35H | 1170-1220 | 11.7-12.2 | >=17 | >=1353 | 33-36 | 263-287 | 120℃ | |

33H | 1130-1170 | 11.3-11.7 | >=17 | >=1353 | 31-34 | 247-271 | 120℃ | |

30H | 1080-1130 | 10.8-11.3 | >=17 | >=1353 | 28-31 | 223-247 | 120℃ | |

45SH | 1320-1380 | 13.2-13.8 | >=20 | >=1592 | 43-46 | 342-366 | 150℃ | |

42SH | 1280-1320 | 12.8-13.2 | >=20 | >=1592 | 40-43 | 318-342 | 150℃ | |

40SH | 1240-1280 | 12.5-12.8 | >=20 | >=1592 | 38-41 | 302-326 | 150℃ | |

38SH | 1220-1250 | 12.2-12.5 | >=20 | >=1592 | 36-39 | 287-310 | 150℃ | |

35SH | 1170-1220 | 11.7-12.2 | >=20 | >=1592 | 33-36 | 263-287 | 150℃ | |

33SH | 1130-1170 | 11.3-11.7 | >=20 | >=1592 | 31-34 | 247-271 | 150℃ | |

30SH | 1080-1130 | 10.8-11.3 | >=20 | >=1592 | 28-31 | 223-247 | 150℃ | |

40UH | 1240-1280 | 12.5-12.8 | >=25 | >=1990 | 38-41 | 302-326 | 180℃ | |

38UH | 1220-1250 | 12.2-12.5 | >=25 | >=1990 | 36-39 | 287-310 | 180℃ | |

35UH | 1180-1220 | 11.8-12.2 | >=25 | >=1990 | 33-36 | 263-287 | 180℃ | |

33UH | 1130-1170 | 11.3-11.7 | >=25 | >=1990 | 31-34 | 247-271 | 180℃ | |

30UH | 1080-1130 | 10.8-11.3 | >=25 | >=1990 | 28-31 | 223-247 | 180℃ | |

28UH | 1020-1080 | 10.2-10.8 | >=25 | >=1990 | 26-29 | 207-231 | 180℃ | |

38EH | 1220-1250 | 12.2-12.5 | >=30 | >=2388 | 36-39 | 287-310 | 200℃ | |

35EH | 1170-1220 | 11.7-12.2 | >=30 | >=2388 | 33-36 | 263-287 | 200℃ | |

33EH | 1130-1170 | 11.3-11.7 | >=30 | >=2388 | 31-34 | 247-271 | 200℃ | |

30EH | 1080-1130 | 10.8-11.3 | >=30 | >=2388 | 28-31 | 223-247 | 200℃ | |

28EH | 1040-1090 | 10.4-10.9 | >=30 | >=2388 | 26-29 | 207-231 | 200℃ | |

Pictures of strong force NdFeB segment magnets

Ningbo Xingde Magnet Co.,Ltd engages in the development and innovation of high permanent NdFeB magnetic material with highly focuses on the quality of products. Special shaped products can be tested and the accuracy of the sizes will be ensured through the test in different temperature and the analysis of related data. Various reliable testing and analysis of the coating also are available by salt spray testing equipments, Constant temperature and humidity tester, and coating thickness detector.